…uhm, you just plug it in, press a button, and “draw up in the air”, right? Like this, no?

But… we know this is not why you came here … you really want to know how this cool toys work! So, let’s get geeky :

There are currently tow kinds of 3D pens, based on their general mechanism:

A. Molten plastic 3D pens

These are also sometimes called FDM (fused deposition modeling) 3D pens, from the functional principle of the most popular type of 3D printer. And they’ve actually been invented as a kind of tool to fix flawed 3D printed plastic models at first.

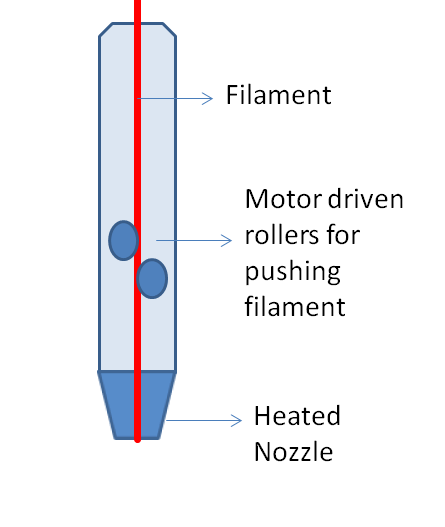

They work by:

- taking in a plastic filament (1.75 mm or 3 mm thick) of either PLA – Polylactic Acid or ABS – Acrylonitrile Butadiene Styrene), which can be either cut in to short “rods”, or it can come in spools

- melting it

- pushing it out of a thing nozzle

…then the pushed out plastic solidifies almost instantly, and stays in whatever shape you’ve drawn it into. Easy right? Actually, here’s a simplified drawing of such a pen:

Anyone with some interest into DIY things has definitely figured out an extra use for these pens by now: household repairs! Since most of the plastics around the house are ABS (one of the filament types supported by most 3D pens), you can obviously use it to stick back broken plastics.

The first generation pens (and some of the current generation “pro” ones) also had a fan blow up cool air to make the plastic cool faster, but after carefully tuning the thermal characteristics of the materials use din the construction of the pen, manufacturers have come to realize that they can do away with the active cooling, making the latest generation pens much smaller and comfortable to use. As an example, check out the size progression from the first 3D pen from 3Doodler, to the latest ultra slim models:

Despite the general functioning principles being the same, and also similar to how 3D printer heads work, the pens themselves all have individual differences (in how they pull/push/twist the filament, how headng works, how molten plastic is extruded to the head, how to change filaments, how easy they clog, how to unclog them etc.) and you can read more about these differences in the article dedicated to the technical details of molten plastic (FDM) pens.

Here are a few of the the molten plastic 3D pens on market today that we’ve enjoyed the most:

B. “Cool ink” UV-hardened photopolymer pens

These are way cooler in principle, since the “cook ink” (a polymer resin) is hardened by shining light on it (UV-light to be more specific) from an LED in the tip of the pen. It’s a safer (no hot tip), and less energy draining (so pens ca be wireless) process, and it looks pretty damn cool:

But the “cool ink” is more expensive than plastic, and so far they don’t seem very suited for thin strands / detail work.

So far there are only a few 3D pens on the market today that utilize this principle. Check them out and see if you think they are something you’d like: