ABS or Acrylonitrile butadiene styrene is one of the most versatile plastics. It’s a petrochemical plastic, and it doesn’t biodegrade easily, but this is a good thing: it lasts, and we generally want the objects around us to last!

If you’re like me, you’re probably surrounded by plastic objects, and more than half of them are probably ABS – the case or keyboard of the device you’re reading this on, the lego brick you just stepped on, the dashboard of your car, you name it! It’s everywhere:

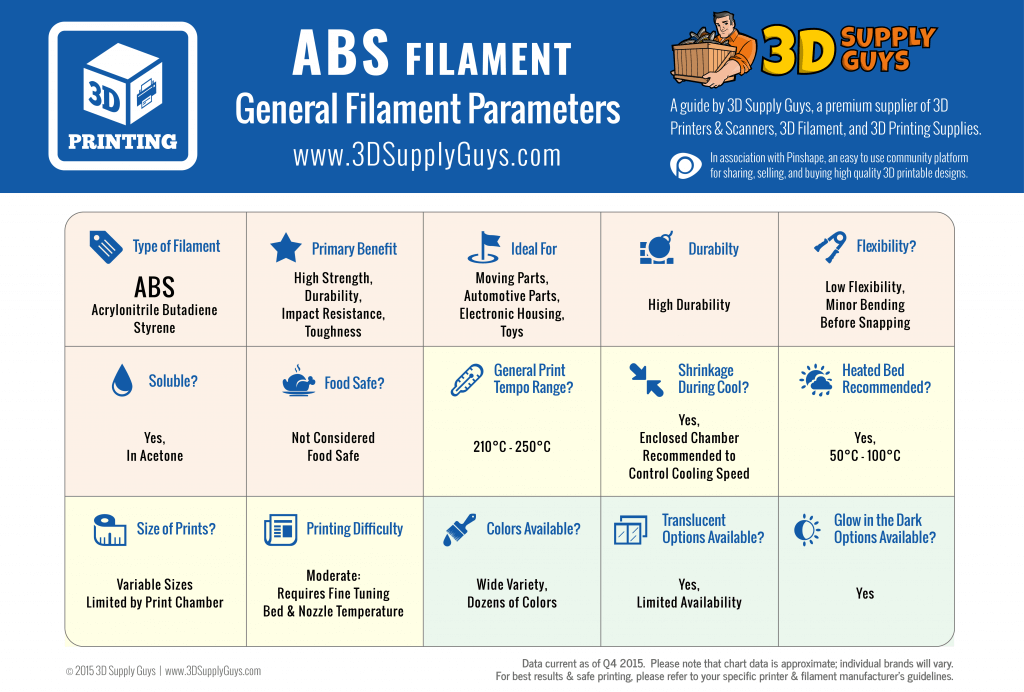

It can give off toxic fumes when burnt (at over 400°C / 752°F – but a 3D pen will never ever get nearly this hot!) or when exposed to strong acids. But kidding aside, ABS is quite safe, and we’re practically surrounded by it anyway.

It is not food-safe though! It usually contains additives that are harmful if eaten, and some of the acids and other chemicals in food may react with ABS making it leach more or less toxic chemicals. There are however ABS food containers and things like knives made from it – we really have no idea how safe these are. General advice is to never draw or print ABS food recipients despite how good they might look – just pick another type of plastic for putting near your food!

Now, leaving aside the warnings above, ABS is the standard prototyping plastic material. Its properties make it awesome for this tasks, even if the final product might be switched to a different plastic.

And there’s on extra cool property to notice in the table above: it’s soluble in acetone. How might this be useful? Well… think about it!

What it actually means is that you can use acetone (a pretty common and easy to procure chemical) to chemically weld ABS models after they have hardened! And, if this wasn’t nifty enough, you can also use acetone to give them a nice shinny finish, a chemical polishing of sorts. Look at this example of a 3D printed ABS model before and after acetone polish:

You can’t pull of this trick with PLA, can you?